Problem

Time is money for companies with food contaminations

The longer it takes to identify the source of a contamination, the greater the financial exposure

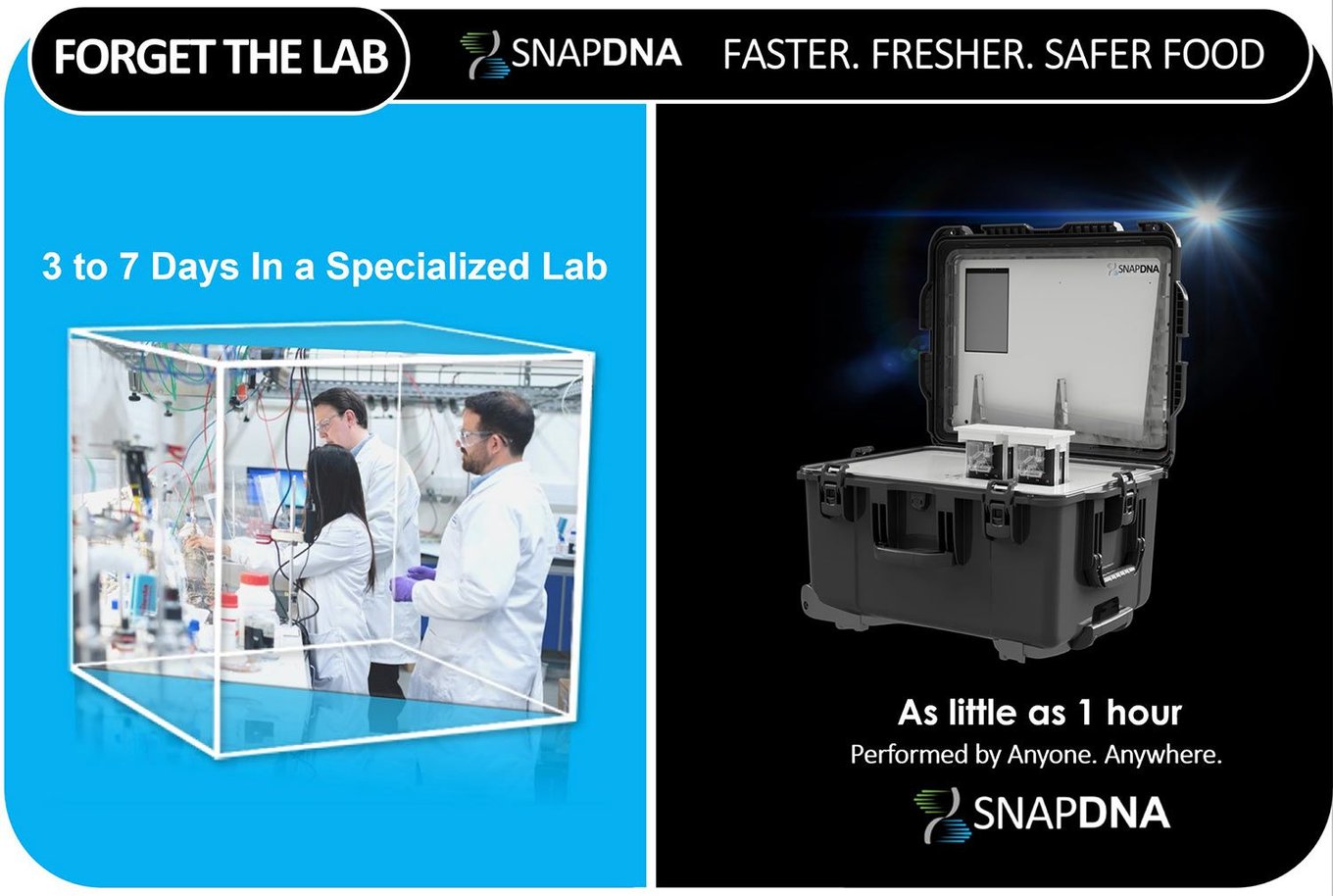

Food companies typically hold product for 3 to 7 days waiting for lab results for pathogens such as Listeria, Salmonella, and E. coli.

A single recall can bankrupt a food company. SnapDNA has quantitative analysis to enable contamination sources to be identified in 1-2 days instead of weeks, months or longer using conventional lab tests.

Solution

Rapid testing means fresher, safer food — faster

SnapDNA can perform the same analysis in as little as 1 hour, saving billions of dollars a year in operational costs and reducing the risk from outbreaks.

Product

SnapDNA:

Superior on-site food testing with AI-driven analytics

Holding product results in huge costs from storage, material handling, labor and inventory dwell time. For example, $30M of SnapDNA rapid testing can save the top 10 poultry processors $1.2B per year in storage-related costs.

We solve business-critical problems by streamlining the supply chain, increasing company margins, and reducing the financial exposure from recalls.

Our instruments are cellular-connected to the SnapDNA cloud, powering sector-specific, predictive analytics to enable, for the first time, a proactive approach to reducing contamination.

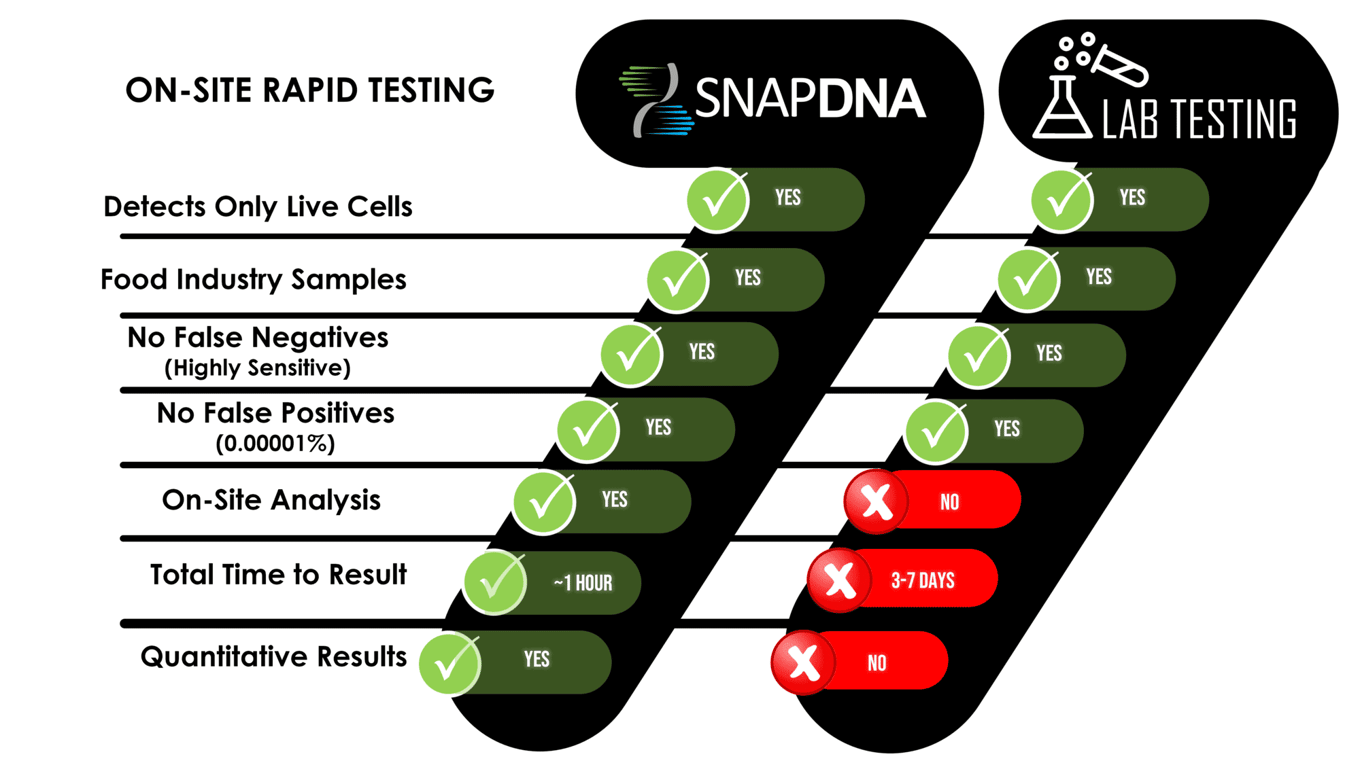

SnapDNA is superior to every other test at every scale, and is the only rapid test that meets every requirement to replace lab testing.

Traction

Customers

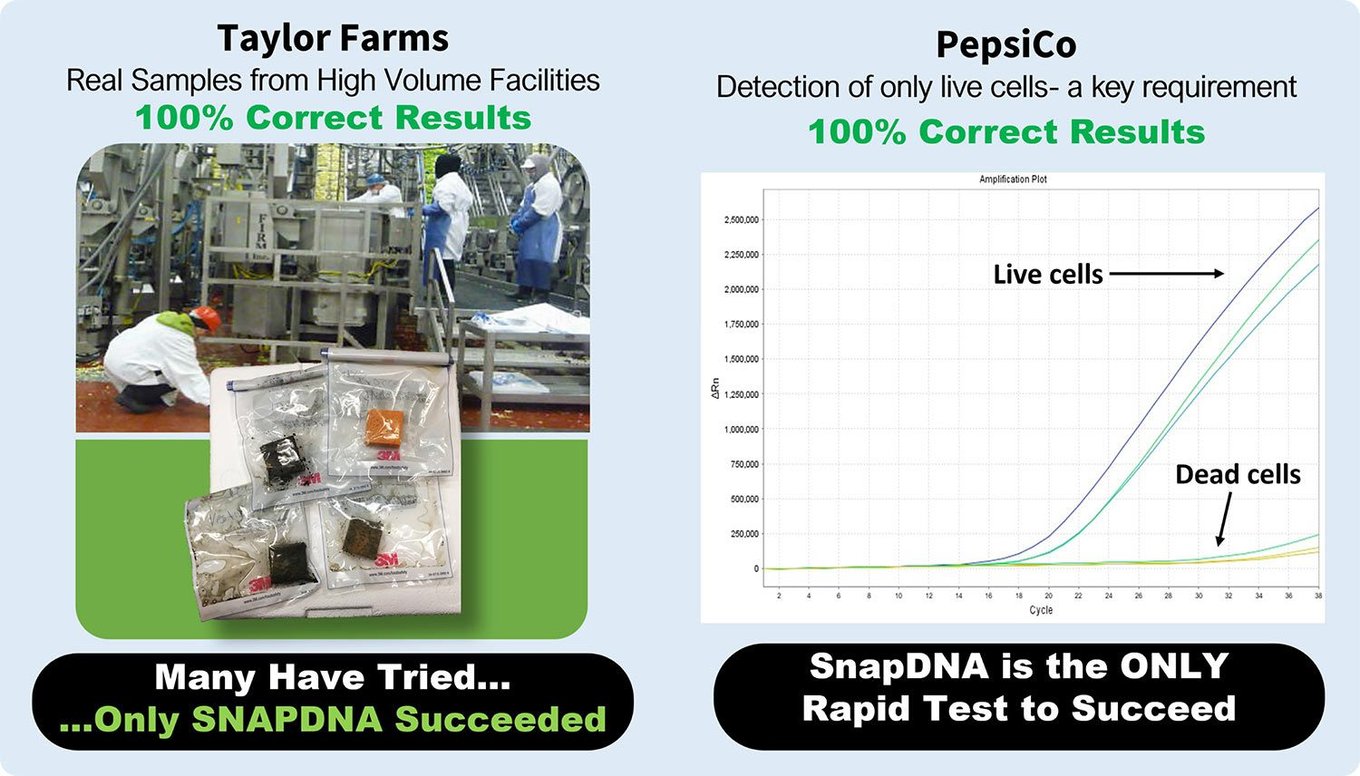

100% success rate in

paid pilot studies

—

Customer evaluation requests

—

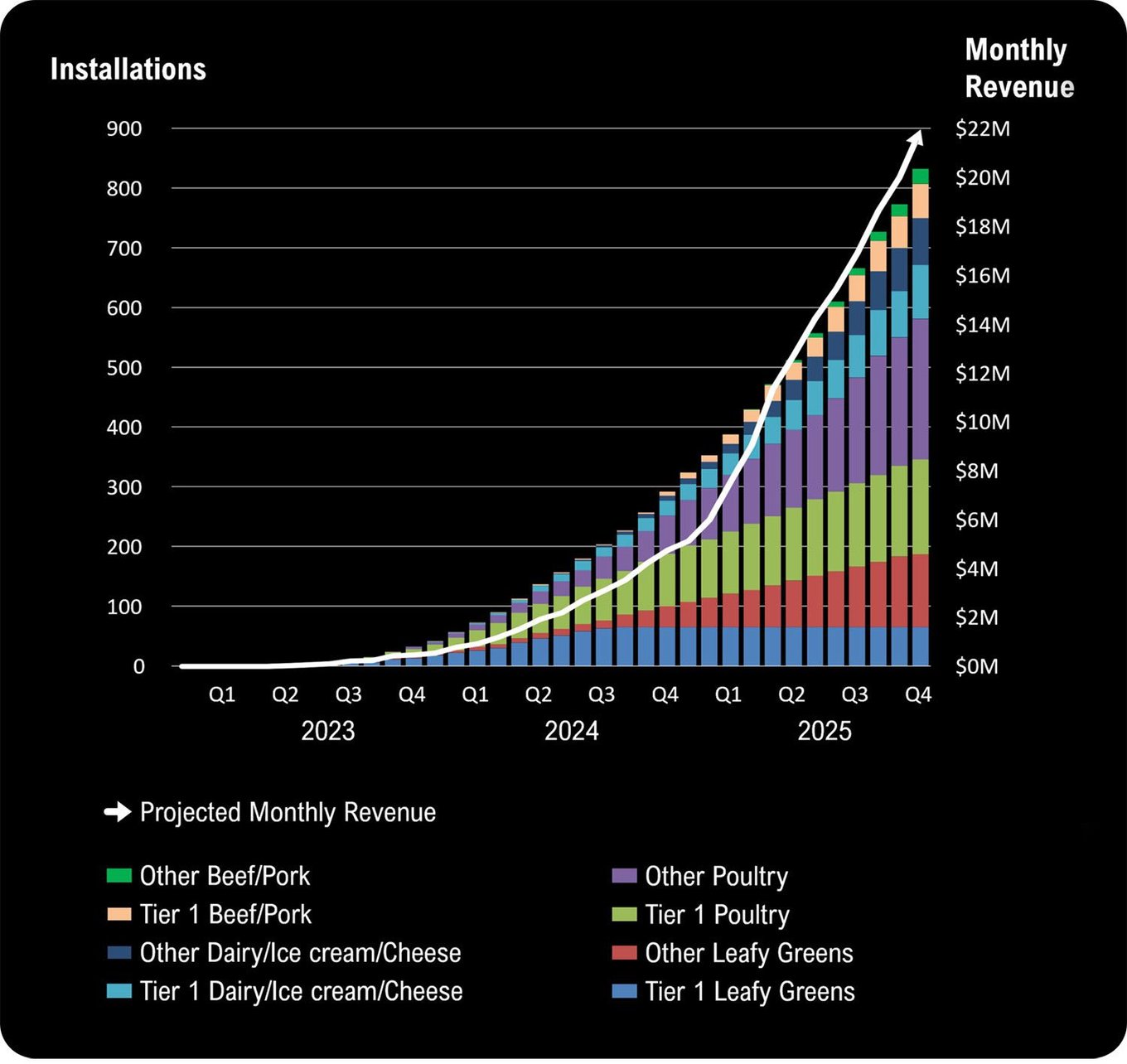

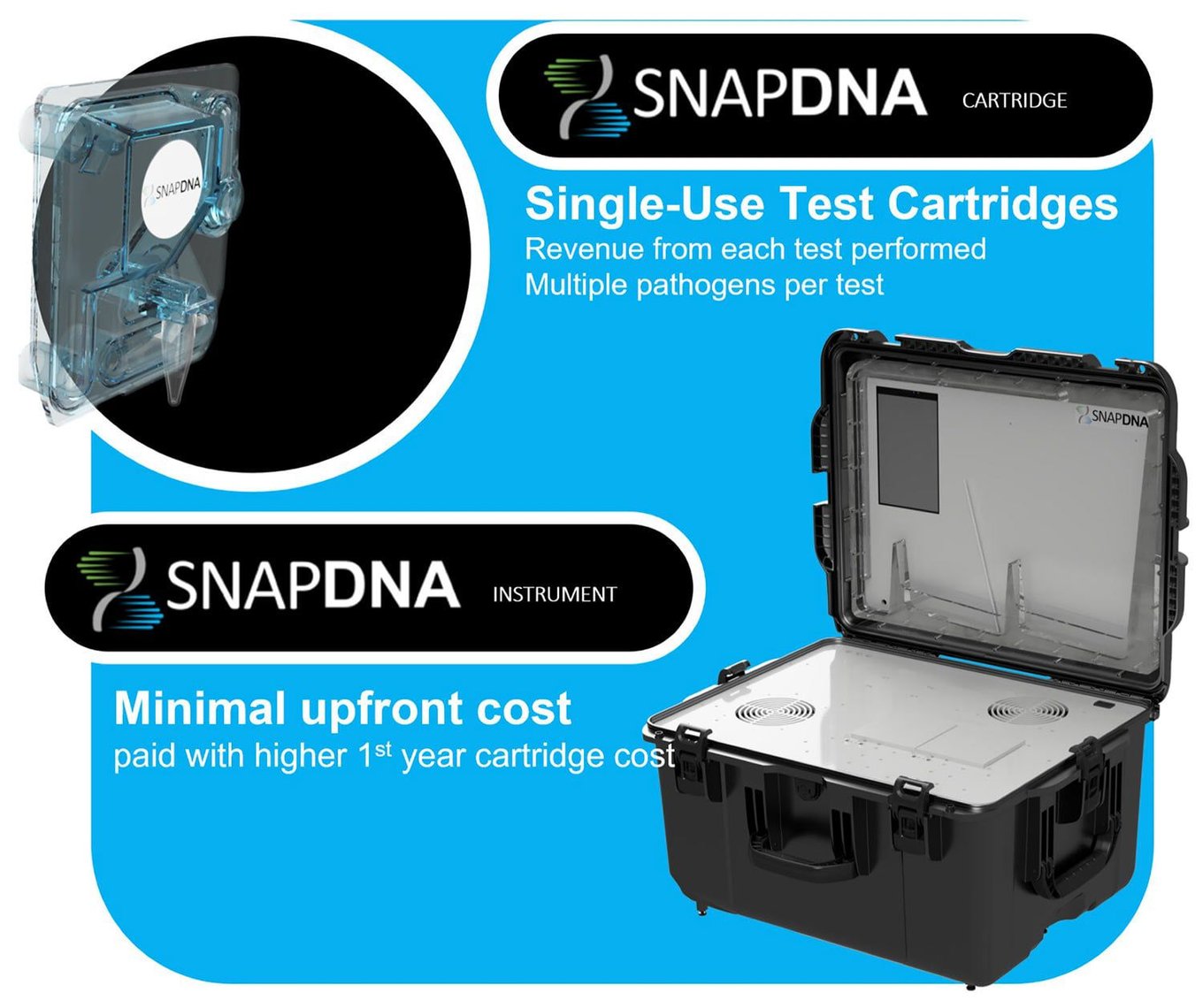

Business model

Commercial-ready prototype system with strong returns

We are looking to fund product launch — not research or development.

We intend to offer a menu of single-use test cartridges for use in the SnapDNA system. These include tests for additional food pathogens, spoilage agents (yeast and mold) and allergens, with cartridges capable of analyzing multiple targets at a time.

Market

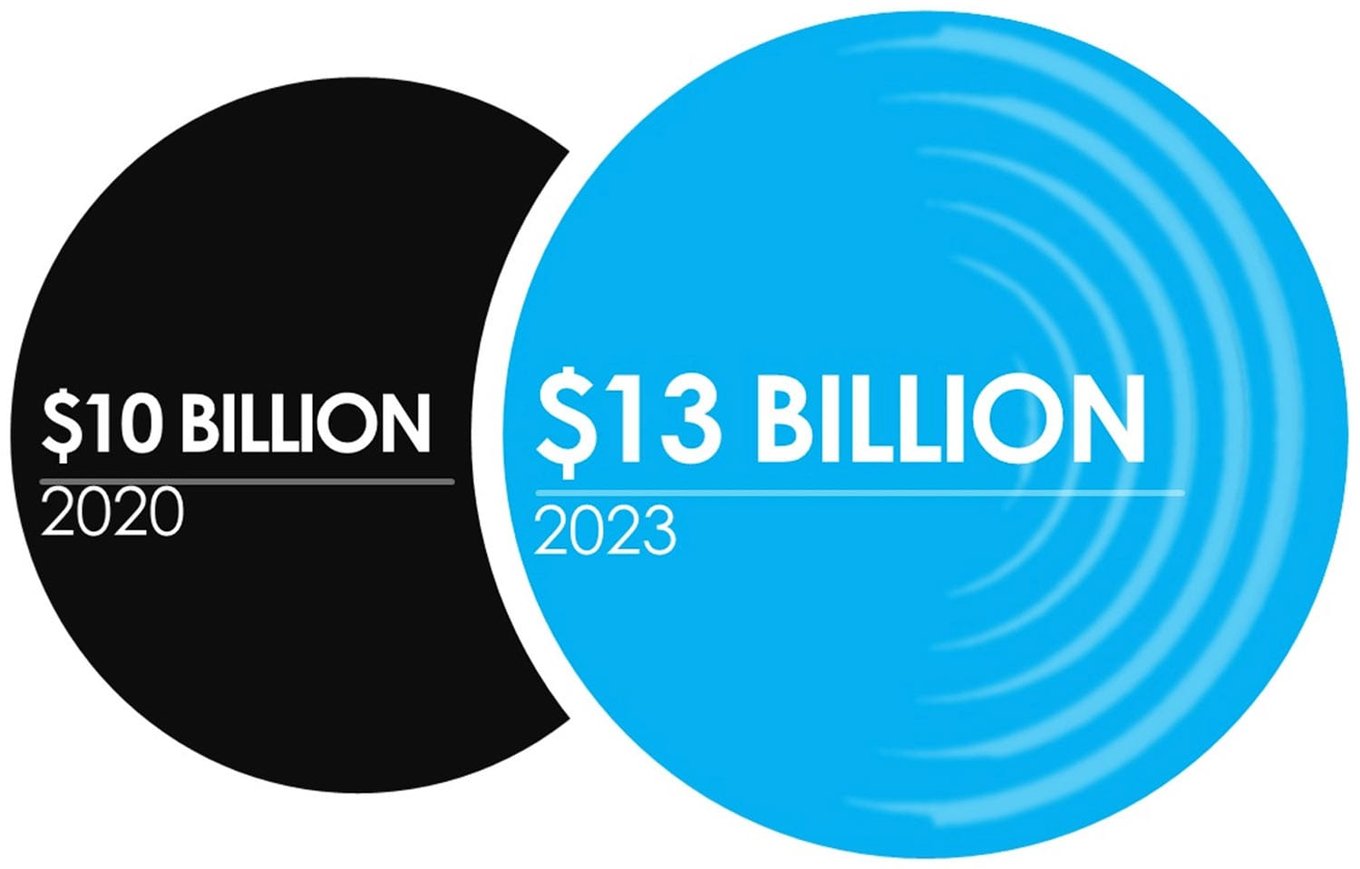

$13B recession-proof

market with 8% CAGR

Food pathogen testing is an existing recession-proof, $13B market growing at over 8% CAGR. There are over 100 million food pathogen tests per year in the US, with nearly half a billion tests per year worldwide.

Competition

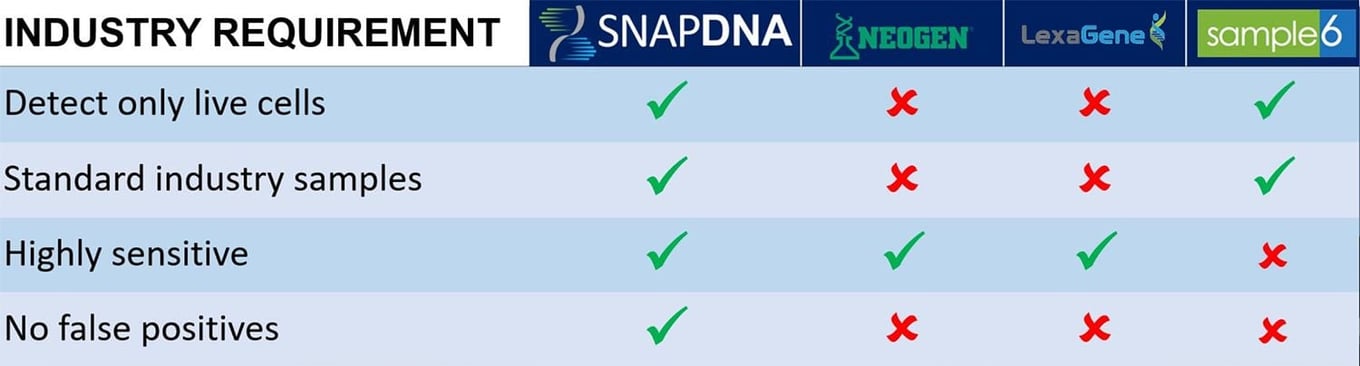

SnapDNA meets every industry requirement

We use a unique new approach to DNA analysis, 10 years in development. All core IP developed in-house with multiple patents/applications, creating a barrier to imitation.

Vision and strategy

Solving global food safety

Our pilots speak for themselves. PepsiCo and Taylor Farms are among the companies that believe in us — because we meet every requirement for point-of-need testing, and we solve business-critical problems.

We have ESG-friendly, commercial ready products made in the USA: an automated diagnostic instrument and low-cost cartridge-based consumables that can be used almost anywhere by almost anyone.

This is a highly multiplexed diagnostic platform with wide applicability in food safety, clinical diagnostics, animal health, water testing and cannabis.

As the number of tests on our platform increases, we intend to offer predictive analytics to enable a proactive approach to contaminations and diseases (instead of a reactionary approach).

—

Exit strategy

—

SnapDNA is poised to revolutionize DNA diagnostics for food testing, water testing, animal health, and clinical diagnostics, providing the potential for a massive exit opportunity.

SnapDNA is poised to revolutionize DNA diagnostics for food testing, water testing, animal health, and clinical diagnostics, providing the potential for a massive exit opportunity.

The company is a target for large life science companies that typically grow through acquisition and pay a premium for platform technologies.

For life science companies that have a large presence in food testing, its value is amplified further because it protects and expands their dominance.

SnapDNA has already caught the attention of some of these companies.

Impact

The cooling industry accounts for around 10% of global CO2 emissions. That is three times the amount produced by aviation and shipping combined.

Virtually all of the 3 billion cubic feet of cold-storage warehouses in the US is used for food. SnapDNA is leading the change to reduce the environmental impact of those storage facilities, which includes greenhouse gases and toxins from the refrigerants and CO2 from the energy usage.

SnapDNA can also help reduce food waste by enabling fresher food for consumers.

Additionally, SnapDNA benefits from a highly diverse workforce.

Summary

10 years ago, food company leadership told SnapDNA the industry desperately needed a 2-hour pathogen test that could replace lab testing. Hundreds of millions of dollars had been invested, but no one had come remotely close.

SnapDNA successfully developed that test. It meets every requirement to replace lab testing including detection of only live, viable cells, and it can be used almost anywhere by almost anyone. Unlike lab tests, the results are quantitative - critical information when tracing a contamination or determining the severity of a positive result.

SnapDNA’s customer waiting list includes some of the largest food companies in the world, some of the largest food contract labs and some of the largest lab suppliers.

We have commercial-ready products made in the USA. We are installing equipment for mass production and targeting first sales later this year.

Food safety is an existing $13B, recession-proof market. The cost savings we provide make us highly valuable in any economy. Inflation, supply chain challenges and weather have devastated margins for many food companies this year. SnapDNA can restore those margins and reduce the risk and exposure from outbreaks and potentially reverse some of the recent increases in food prices.

SnapDNA can reduce the environmental impact of cold storage and enable fresher, safter food for everyone.

Oops! We couldn’t find any results...

Oops! We couldn’t find any results...